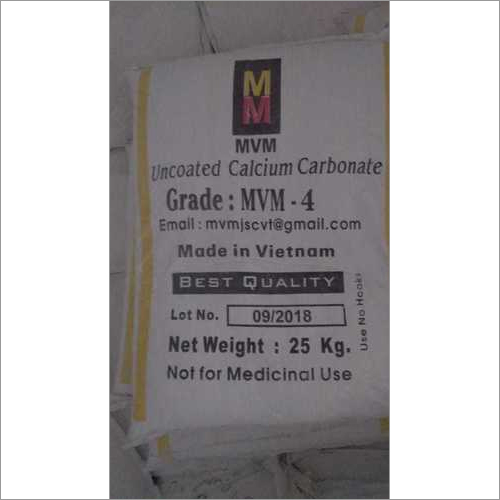

Uncoated vietnam Calcium Carbonate

Price 9.0 INR/ Kilograms

MOQ : 25 Kilograms

Uncoated vietnam Calcium Carbonate Specification

- Form

- Powder

- Material

- Uncoated Vietnam Calcium Carbonate

- Hardness

- 3 (Mohs)

- Packaging Type

- PP woven bag with inner liner, 25 kg or customized

- Usage & Applications

- Filler in plastics, rubber, paints, paper, PVC, masterbatches, adhesives, and sealants

- Type

- Industrial Mineral

- Material Feature

- High brightness, high purity, low oil absorption, low iron content, fine particle size

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Grade

- Industrial Grade

- Melting Point

- 825C (Decomposition temperature)

- Color

- White

Uncoated vietnam Calcium Carbonate Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Sample Available

- Yes

- Main Domestic Market

- All India

About Uncoated vietnam Calcium Carbonate

We proudly announce that we all India Distributors of world class Ground Calcium Carbonate (GCC) sourced from the whitest, purest and less abrasive mines in Vietnam.

The properties of our Uncoated and Coated Calcium Carbonate (Stearic Acid 1.2%) are:

Grade: MVM1. D50: 1.7+-.3. D97: 10+-1. Mesh Size ~2000

Grade: MVM2. D50: 2.5+-.3. D97: 14+-1. Mesh Size ~1500

Grade: MVM3. D50: 3+-.3. D97: 20+-1. Mesh Size ~1000

Grade: MVM4. D50: 3.7+-.3. D97: 25+-1. Mesh Size ~800

Exceptional Purity and Brightness

Boasting a minimum CaCO purity of 98% and brightness of at least 98%, our uncoated Vietnam Calcium Carbonate delivers a brilliant white appearance. The material contains low iron and moisture, ensuring a high-grade industrial mineral suitable for sensitive applications.

Customizable Particle Size for Diverse Needs

The products particle size (D50) is customizable between 2 and 8 microns for tailored performance. This fine particle distribution enhances dispersion and compatibility with various polymers, paints, and paper products, meeting the specific requirements of manufacturers.

Widely Applicable Across Industries

Uncoated Vietnam Calcium Carbonate serves as an essential filler in numerous applications. From plastics and rubber to adhesives and sealants, its high purity, brightness, and low oil absorption improve material properties, optimize costs, and advance final product quality.

FAQs of Uncoated vietnam Calcium Carbonate:

Q: How is uncoated Vietnam Calcium Carbonate typically processed before shipping?

A: Uncoated Vietnam Calcium Carbonate undergoes rigorous grinding and classification to achieve the specified particle sizes (D50: 28 microns). It is further quality checked for purity, brightness, moisture, and mesh residue before being packed securely in PP woven bags with inner liners.Q: What are the main benefits of using this calcium carbonate in industrial applications?

A: The advantages include high brightness for improved visual appeal, superior purity (98% CaCO), low moisture, and iron content, as well as optimal particle dispersion. These features enhance product durability, processing efficiency, and the smoothness of end materials.Q: When should uncoated calcium carbonate be selected over coated varieties?

A: Uncoated calcium carbonate is ideal when surface modification is unnecessary, particularly in applications where strong matrix bonding and dispersion are desired without added hydrophobic properties, such as in paints, paper, and some plastic formulations.Q: Where is this product most commonly used?

A: This calcium carbonate is extensively utilized as a filler in the production of plastics, rubber, paints, paper, PVC, masterbatches, adhesives, and sealants, where its high purity and fine particles deliver superior performance.Q: What is the recommended packaging for safe transport and storage?

A: The product is packed in 25 kg polypropylene woven bags with inner liners to preserve quality and prevent moisture absorption. Custom packaging options are also available according to client requirements.Q: How does the fine particle size influence product usage?

A: Fine and customizable particle sizes allow for better distribution within host matrices, leading to enhanced mechanical properties, greater smoothness, and better surface finishes in final products across various industries.Q: What distinguishes Vietnams calcium carbonate in terms of quality?

A: Vietnams calcium carbonate is prized for its outstanding purity, high brightness, and low iron and moisture levels. Stringent mining and processing standards ensure a consistent and reliable industrial mineral favored globally by exporters and manufacturers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

GST : 07AAPFP7736D1ZX

PLOT NO. 25, POCKET - B, SECTOR- 3, DSIIDC INDUSTRIAL AREA, BAWANA,North West Delhi - 110039, India

Phone :08045816617

|

|

PRESTIGE DISTRIBUTORS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry