Optical Brightener for CPW

Optical Brightener for CPW Specification

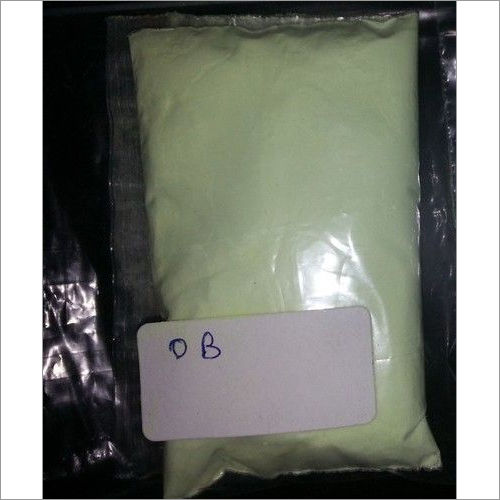

- Type

- Chemical Powder

- Material Feature

- Optical Brightener

- Density

- Gram per cubic centimeter(g/cm3)

- Grade

- Industrial

- Melting Point

- Not available

- Weight

- Not available

- Color

- Light Yellow

About Optical Brightener for CPW

We import Optical Brightener OB, Optical brightener OB1, Optical Brightener FP127 and also supply GPPS brightener and HIPS brightener.

We supply these in PVC, PS, PE, ABS, HD, LD, PP, HM, HIPS, GPPS, ABS, masterbatches, Compounds, pipes and profiles industry, apart from Paint, printing ink, artificial fibre, acetate fibre, etc.

Exceptional Brightening Efficiency

This optical brightener is formulated to provide maximum whiteness and brightness in CPW applications. Its efficacy in small doses makes it an economical and powerful additive for industrial use where appearance and optical quality are priorities.

Industrial Versatility

Applicable across numerous sectors, our optical brightener seamlessly integrates with chlorinated paraffin wax in fields such as plastics, rubber, and coatings. Its compatibility and reliability make it a preferred choice for manufacturers demanding consistent, high-quality results.

FAQs of Optical Brightener for CPW:

Q: How is the optical brightener for CPW used in industrial applications?

A: The optical brightener is blended with chlorinated paraffin wax (CPW) during manufacturing to enhance visual brightness and deliver a cleaner appearance to the end product. Its powder form allows for easy dispersion and effective integration.Q: What are the key benefits of using this optical brightener in CPW formulations?

A: This product improves the visual whiteness and clarity of CPW, making finished goods more attractive and appealing. Enhanced brightness also helps mask yellowing over time, improving the longevity and perceived quality of products.Q: Where is this optical brightener manufactured and supplied from?

A: The optical brightener is produced and distributed in China, with robust operations as an exporter, importer, manufacturer, supplier, and trader to meet global industrial requirements.Q: When should I incorporate the optical brightener during the CPW preparation process?

A: It is most effective to add the optical brightener during the mixing stage of CPW processing. This ensures even distribution and optimal brightening performance throughout the batch.Q: What is the typical process for integrating the optical brightener into CPW?

A: The optical brightener is measured in the required quantity and mixed uniformly with CPW under standard industrial conditions. Due to its powdery consistency, it disperses smoothly and does not require special handling equipment.Q: Can you outline the primary usage sectors for this optical brightener?

A: Industries such as plastics manufacturing, lubricants, coatings, and rubber processing commonly use this optical brightener to improve CPWs optical properties, resulting in brighter, more attractive products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Optical Brighteners Category

OB1

Price 2500 INR

Minimum Order Quantity : 1 Kilograms

Weight : 25 kg (per bag or drum)

Color : Yellowish Green

Type : Other, Brightener

Material Feature : High whitening efficiency, Excellent thermal stability, Good compatibility

Optical Brightener OB for Paints

Price 6400 INR

Minimum Order Quantity : 1 kg Kilograms

Weight : 25 kg (standard packaging)

Color : Greenish Yellow

Type : Other, Fluorescent Whitening Agent

Material Feature : High Purity, Good Solubility in Organic Solvents, Strong Fluorescence

Optical Brightener for PVC Marble Sheet

Price 6400 INR

Minimum Order Quantity : 1 Kilograms

Weight : Customizable

Color : Light Yellow

Type : Other, Powder

Material Feature : Optical Brightener

Optical brightener for flexible pipes

Price 5000 INR

Minimum Order Quantity : 1 Kilograms

Weight : Depends on packaging size

Color : Light yellow

Type : Other, Powder

Material Feature : High brightness enhancement

GST : 07AAPFP7736D1ZX

|

|

PRESTIGE DISTRIBUTORS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry